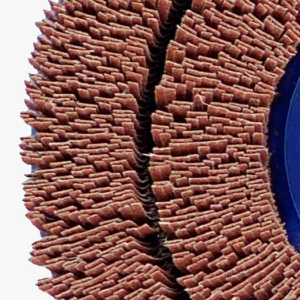

The deburring grinding discs from the FAPI-SOLID series are the ideal tool for maximum deburring performance. A solid tool for solid results. Every feed rate that can be moved faster, every minute less needed to reach your target, brings enormous savings potential. This is our incentive and can be implemented with our FAPI-SOLID series.

FAPI-SOLID achieves a process improvement due to the often higher use of abrasives. It is deburred and rounded faster and in a shorter time. Convince yourself of our new series FAPI-SOLID.

We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

- A wide variety of trim materials

The correct selection of the type of abrasive cloth can have an enormous influence on the deburring process. The optimal design of the FAPI-SOLID deburring grinding disc can be determined from the process parameters, the material to be processed, the material thickness and the desired surface quality or the desired roughness depth.

- Picard tip

The coarser the grain size of the FAPI-SOLID deburring sanding disc is selected, the stronger the edge rounding on the workpiece will be.

- Shortest process times

The deburring and throughput times can be significantly shortened due to the high abrasive content, the special tool design and the lamella arrangement. Thanks to the high density of the number of lamellas and the special properties of the abrasive structure, intensive edge rounding can be achieved.

- Made in Germany

Without exception, all Picard tools are produced in Germany. High quality and optically outstanding grinding tools are the results of our production and you, as our customer, benefit from this.

We have the optimal type of trim for every material to be processed in order to achieve a perfect and solid result.

You can choose between the grain types aluminum oxide, zirconium corundum, silicon carbide or variants of the ceramic line.Why the different stocking arrangements?

The single-row trim is our standard version. Here we can influence the hardness or flexibility as well as the removal rate by using different abrasive cloth variants.

The double-row version is the variant with the highest flexibility. By dividing the fill width, the fill can adapt even better to the edge and thus also deburr smaller cut-outs better. The facing hardness can in turn be adjusted by using our abrasive cloth variants.FAPI-M14

Ø 115 mm | CWFAPI-TRIM

Ø 115 mm | CW

Ø 125 mm | CW+CCWFAPI-FIT

Ø 150 mm | CW+CCW

FAPI-150

Ø 150 mm | CW+CCW

FAPI-180

Ø 180 mm | CW+CCW

FAPI-250

Ø 250 mm | CW+CCW

*CW = clockwise rotation | CCW = counter-clockwise rotation

For example, after the sheet metal has been lasered, punched, flame cut or cut with a water jet, a burr usually forms at the entry and exit points. This can best be removed using the FAPI-SOLID deburring grinding discs. The deburring or edge rounding of sheet metal parts is carried out on automatic, stationary deburring machines.Our FAPI-SOLID deburring grinding discs can be used on deburring machines from the following manufacturers:

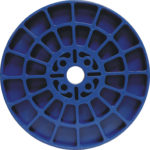

TIMESAVERS | LISSMAC | COSTA | EMC | DMC | HEESEMANN | GECAM | LOEWER | Q-FIN | RWT | VG MACHINES | VIET | WEBER | STEELMASTER | FLADDER | HOUFEK | KUHLMEYER | LOESERDiameter: 150 mm

Stocking height: 50 mm

Drilling:: 25 mm + Driver holes

+ Quick release system

Total height: 65 mmFacing width:

38 mm (Single row)

37 mm (Y variant)

30 + 20 mm (Double row)