The deburring discs of the FAPI-M14 125 series are the ideal tool of hand operated deburring. The integrated M14 thread can be adjusted to regulated angle grinders and are especially fit for smaller and medium series, in which the purchase of an automatic deburring machine is not worthwhile.

We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Product features

Shortest set-up times The M14 thread allows the user to easily mount the FAPI-M14 125 deburring discs on the angle grinder.

A wide variety of facing materials The selection of different densities, fill variants, abrasive cloth and abrasive fleece types can have a decisive influence on the deburring process. The optimum design of the deburring disc FAPI-M14 125 can be determined based on the following process parameters: the material being processed, material thickness and the desired surface quality or the desired surface roughness.

- Picard tip

The coarser the grain size of the deburring disc FAPI-M14 125 is selected, the stronger the edge rounding on the workpiece will be.

Uniform edge rounding The new FAPI-M14 125 deburring disc completely eliminates the frequent problem of different rounding/chamfering across the sheet edges when deburring manually with abrasive flap discs. It is also easy to debur longer edges as well as cut-outs and drill holes – without the user needing to apply excessive force.

Individual flap positions The deburring disc FAPI-M14 125 has abrasive cloth flaps attached to the face, which are supported by non-woven abrasive flaps. By special adjusting the lamellae it is possible to produce the deburring disc FAPI-M14 125 individually according to the respective processing.

Made in Germany Without exception, all Picard tools and, of course, our deburring disc series are produced in Germany. High quality and optically outstanding grinding tools are the results of our production and you, as our customer, benefit from this.

Facing Types

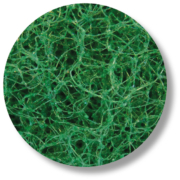

PICARD GREEN

(standard-fleece) | The soft fleece!

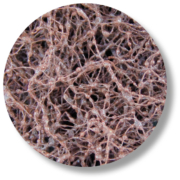

PICARD BROWN

(standard-fleece) | The Allrounder!

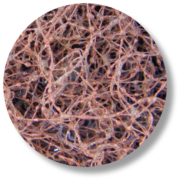

PICARD MAROON

(standard-fleece) | Sets standards in removal!

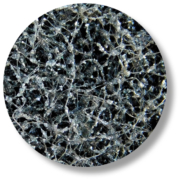

PICARD SAND

(special-fleece) | The one with the bite!

PICARD DARKGREY

(premiun-fleece) | The smooth one!

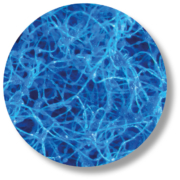

PICARD BLUE

(premium-fleece) | The self-sharpener!

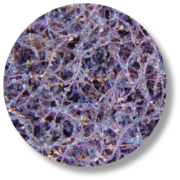

PICARD VIOLET

(premium-fleece) | A noble cause!

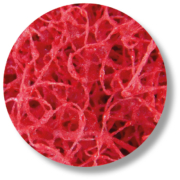

PICARD RED

(special-fleece) | Rough and strong!

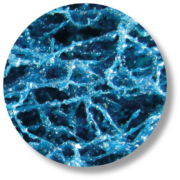

PICARD DARKBLUE

(special-fleece) |Wide, sturdy and flexible!

PICARD YELLOW

(special-fleece) | Wet & Dry! The versatile!

PICARD GRV

(special-fleece) | The water-resistant!

Für nähere Informationen zu den Schleifvliesqualitäten klicken Sie bitte hier.

Jetzt auch als doppelreihige Variante erhältlich!

Durch den größeren Durchmesser kann unseren Entgratschleifteller mit dem M14-Gewinde auch mit doppelreihigem Besatz gefertigt werden. Der Vorteil für Sie – mehr Besatz, mehr Abtrag!

Facing varieties

single-row

single-row

Standard variant with compact arrangement. Hardness and flexibility as well as the removal rate can be influenced by using different abrasive fleece variants in combination with abrasive cloth.

dimensions

diameter: 125 mm

facing width: 30 mm

facing height: 31 mm

total height: 40 mm

thread: M14

double-row

double-row

This facing arrangement offers a high degree of flexibility. By dividing the facing width, the facing can adapt even better to the edge and therefore also deburr smaller cut-outs better. The fill hardness can be adjusted by selecting the abrasive fleece qualities.

dimensions

diameter: 125 mm

facing width: 2 x 20 mm

facing height: 31 mm

total height: 40 mm

thread: M14