THE NEW GENERATION OF GRINDING BLOCKS!

REDUCE SETUP COSTS BY UP TO 80%!

OUR SOLUTION MAKES THE TIME-CONSUMING REMOVAL

OF THE POWER BELT FROM THE MACHINE A THING OF THE PAST.

THE NEW GENERATION OF GRINDING BLOCKS!

UNBEATABLE SETUP TIMES

All you need is a “SNAP”!

Tool changes have never been

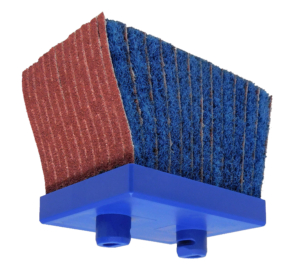

as easy as with the two-part SNAP system!

SECURE TOOL FASTENING

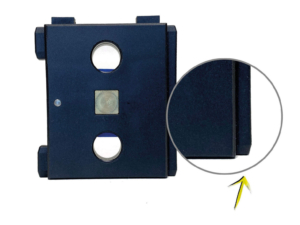

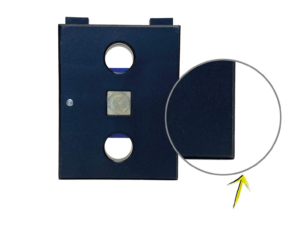

Thanks to our innovative tool fastening system,

twisting/slipping of the sanding blocks

on the power belt is a thing of the past.

.

INDIVIDUAL SOLUTIONS

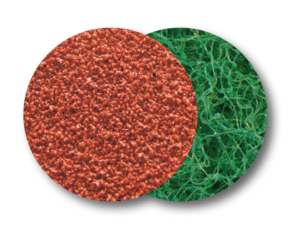

A selection of trim types specially tailored to

the material being processed

offers the possibility of customizing the sanding block

to suit specific customer requirements.

Key tool

SNAP-KEY

base carrier EVO SNAP

anti-twist protection

FAPI-EVO SNAP

Family

BASIC CARRIER MODELS

The new and improved version of our FAPI-EVO grinding blocks consists of two parts. The lower part, the FAPI-EVO SNAP base carrier, is mounted on the power belt as usual using pan-head screws.

Depending on the machine type (e.g. SBM*1000 or SBM*1500), the base carriers are available with or without wings.

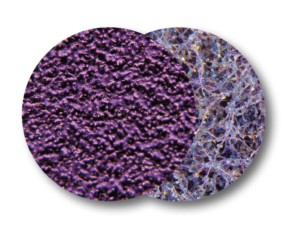

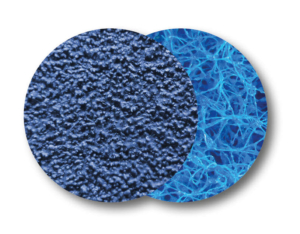

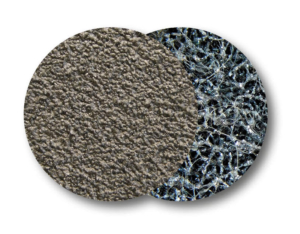

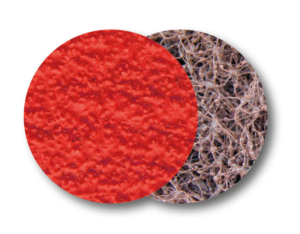

FACING TYPES

Like its predecessor, the upper section, the FAPI-EVO SNAP grinding block, can be selected with different facing types to suit the machining process.

| BASIC-Line (Standard) |

| aluminum | steel | stainless steel |

| VIOLET-Line (Premium) |

| stainless steel |

| BLUE-Line (Premium) |

| steel | high-alloy steel |

| BLACK-Line (Premium) |

| aluminum | plastic |

| RED-Line extra strong (special) |

| stainless steel |

Compared to conventional EVO grinding blocks, where the entire block has to be removed from the power belt, the SNAP variant only requires the base carriers to be fitted once. Only the grinding block with the selected facing type is detached from the base carrier using the SNAP KEY

and replaced by simply snapping them back into place. It is no longer necessary to completely remove the power belt from the machine.