With regard to optimum performance, where high efficiency and the highest possible sanding performance are required, the coordination between the sanding belt and contact wheel is of crucial importance in the belt sanding process. The hardness, type and design of the backing pad are decisive factors in the interaction between the machine, contact wheel, abrasive belt and workpiece. The contact wheel must adapt to the shape of the workpiece with the abrasive belt, provide the required sanding performance and achieve the desired sanding pattern. The structure and design of the contact wheel coating can only be better determined from the sum of these factors. The most common materials for the contact wheel pad are NBR (rubber), plastic, plastic foam and, in special cases, fabric materials. Contact wheels of the FAPI-PA series are provided with a wear-resistant and oil and grease-resistant NBR (“rubber”) coating. The height of the covering can be selected variably, with the standard height proven in practice being 20 mm. The higher the coating, the more elastic and therefore softer the contact wheel surface appears.

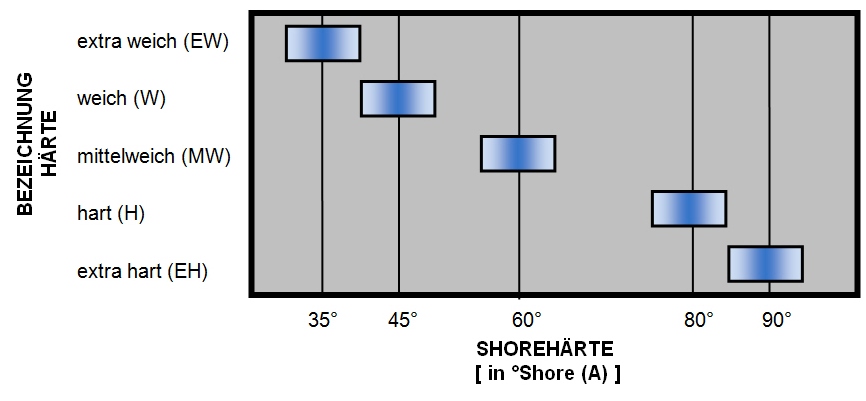

Coating hardness

The right choice of design and contact wheel hardness always depends on the individual application!

Executions

Contact wheel FAPI-PA GLATT Aluminum core with a smooth NBR coating Diameter: 75 to 450 mm Width: 20 to 200 mm Bore: as specified – other dimensions on request –

Contact wheel FAPI-PA MILLED Grooves are milled into the NBR coating. These grooves can be produced in a wide variety of widths, depths and angles. Diameter: 75 to 450 mm Width: 20 to 200 mm Bore: according to specification – other dimensions on request –

Contact wheel FAPI-PA FREQUENCY DAMPED A further development of the milled version. Grooves are milled into the NBR coating with a groove width/groove depth/web width ratio specially developed by us. This achieves significant frequency damping and a reduction in the sound level of up to 5 dB(A) during the belt grinding process. Diameter: 75 to 450 mm Width: 20 to 200 mm Bore: according to specification – other dimensions on request –

Application recommendations

| Grinding operation: | Cylindrical grinding, surface grinding, heavy-duty grinding and roughing work |

| Type of cut: | Wet and dry sanding |

| Handling: | Automated grinding, hand-guided machines, manual grinding trestle/backstand, robot grinding |

| Cutting speed: | maximum 50 m/s recommended 36 m/s |