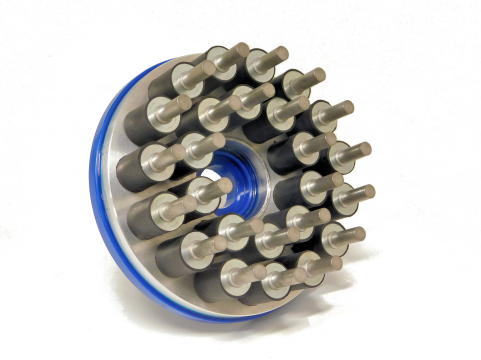

FAPI-TRIM

Ø 125 mm | RL+LL

The FAPI-PIN slag plate is the optimal tool for removing slag caused by flame cutting processes. The hardened pins are cast together in a base so that they cannot come loose from the flexible mass. FAPI-PIN offers a high level of flexibility in order to be able to remove slag of varying degrees, among other things. Convince yourself of our new slag disc FAPI-PIN.

Do you have questions? We are happy to help! The PICARD team is at your disposal at any time.

Product features

Shortest process times The deburring and throughput times can be significantly reduced compared to a conventional grinding process by using the FAPI-PIN slag disc.

Made in Germany Without exception, all Picard tools are produced in Germany. High quality and optically outstanding grinding tools are the results of our production and you, as our customer, benefit from this.

Mountings

FAPI-FIT

Ø 150 mm | RL+LL

FAPI-150

Ø 150 mm | CW+CCW

FAPI-180

Ø 180 mm | CW+CCW

FAPI-250

Ø 250 mm | RL+LL

*CW = clockwise rotation | CCW = counter-clockwise rotation

Applications

Process steps such as oxyfuel or plasma cutting cause very pronounced slag that adheres to the edge of the jet exit side and partially to the surface. In preparation for further process steps such as coating, the slag must be removed in advance, the edges rounded and any oxide layers on the surface removed. This can best be implemented using the slag plate FAPI-PIN. Slag removal is carried out on automatic, stationary deburring machines.

Our slag plates FAPI-PIN can be used on deburring machines from the following manufacturers:

TIMESAVERS | LISSMAC | COSTA | EMC | GECAM | LOEWER | Q-FIN | RWT | VG MACHINES | WEBER | FLADDER