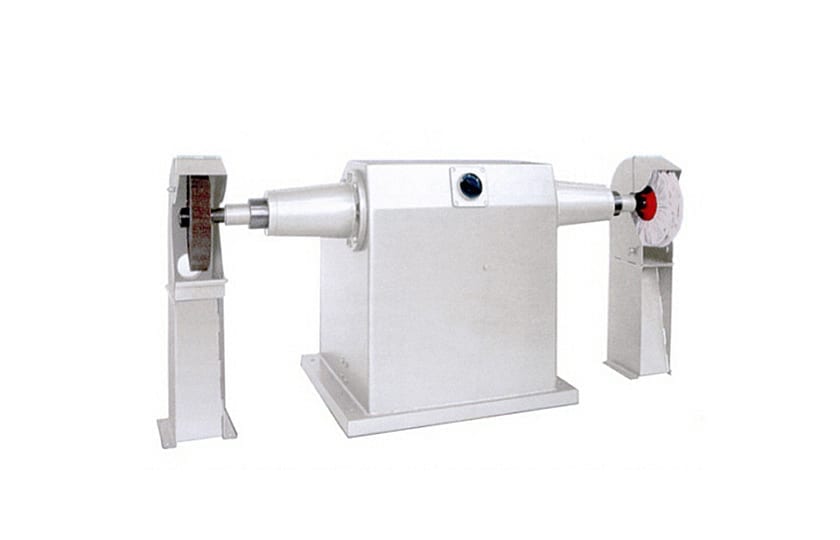

The belt grinding and polishing machines of the SMZ 57 series can be used in a variety of ways with their different motor powers. The belt grinding and polishing machines of the SMZ 57 series can be used in a variety of ways with their different motor powers.

The highlight is the machine’s split spindle shafts, so that three different speeds can be preset for each shaft via a V-belt drive.

Standard sanding belts with a length of 3,500 mm and a width of up to 100 mm can be used on the machine. The maximum dimensions of the Picard contact disks are Ø 450 x 100 mm with a bore of 35 mm.

Not suitable for aluminum processing!

- Very stable construction

The stable design of the SMG 57 series ensures continuous, vibration-free running during the machining process. - Stand version with 2 stand heights

The belt grinding and polishing machine can be equipped with a low column (600 mm) as well as a high column (1,000 mm) of the stand. - Double-sided version

Machine is always delivered in a double-sided version. At the customer’s request, a page can be made “blind”. This means that a cost-effective and quick expansion option is always available. - Split spindle shafts

The SMZ 57 series is equipped with a motor integrated in the stand and has split spindle shafts. 3 speeds in the range of 1,200 1/min and 3,500 1/min can be set for each spindle shaft. These settings can be different. - Space-saving design

The vertical arrangement of the belt guide and the belt protection hoods results in a very space-saving design, which makes it possible to set up several machines in a very small space. - Wide range of accessories

The extensive range of accessories offers you the option of quickly converting to other applications. - Fast belt tension

Thanks to the quick belt tension, the sanding belt can be changed quickly and easily. This means that the machine can be converted to other sanding belts in a very short time. - Main switch with motor protection and undervoltage release

To ensure the safety of our machines, all of them are equipped with motor protection and undervoltage release. - Newest regulations

Protective devices and steel protective hoods comply with the latest regulations and are constantly checked. - CE conformity

For us, legal conformity is a matter of course and has just as high a priority as the long-term, targeted and high manufacturing quality of our products.

waves-Ø: 35 mm

max. contact disk Ø: 450 mm

max. polishing wheel Ø: 500 mm

Voltage: 400 V, 50 Hz

Operating mode: S1, IP 54JTNDdGFibGUlMjBzdHlsZSUzRCUyMndpZHRoJTNBJTIwMTAwJTI1JTNCJTIwZm9udC1zaXplJTNBJTIwMTBweCUzQiUyMiUyMHN1bW1hcnklM0QlMjIlMjIlMjBjZWxsc3BhY2luZyUzRCUyMjAlMjIlM0UlM0Njb2xncm91cCUzRSUyMCUzQ2NvbCUyMHdpZHRoJTNEJTIyNDUlMjIlMjAlMkYlM0UlMjAlM0Njb2wlMjB3aWR0aCUzRCUyMjU1JTIyJTIwJTJGJTNFJTIwJTNDY29sJTIwd2lkdGglM0QlMjI3NSUyMiUyMCUyRiUzRSUyMCUzQ2NvbCUyMHdpZHRoJTNEJTIyNTUlMjIlMjAlMkYlM0UlMjAlM0Njb2wlMjB3aWR0aCUzRCUyMjU1JTIyJTIwJTJGJTNFJTIwJTNDY29sJTIwd2lkdGglM0QlMjI5NSUyMiUyMCUyRiUzRSUyMCUzQ2NvbCUyMHdpZHRoJTNEJTIyNDUlMjIlMjAlMkYlM0UlMjAlM0Njb2wlMjB3aWR0aCUzRCUyMjYwJTIyJTIwJTJGJTNFJTIwJTNDY29sJTIwd2lkdGglM0QlMjI1NSUyMiUyMCUyRiUzRSUzQyUyRmNvbGdyb3VwJTNFJTBBJTNDdGJvZHklM0UlMEElM0N0ciUyMGFsaWduJTNEJTIyY2VudGVyJTIyJTNFJTNDdGglMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAycHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItdG9wJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItcmlnaHQlM0ElMjAwcHglM0IlMjBiYWNrZ3JvdW5kJTNBJTIwJTIzZmZmJTNCJTIyJTIwcm93c3BhbiUzRCUyMjIlMjIlM0UlM0NzdHJvbmclM0VUeXAlM0MlMkZzdHJvbmclM0UlM0MlMkZ0aCUzRSUzQ3RoJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXRvcCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXJpZ2h0JTNBJTIwMHB4JTNCJTIwYmFja2dyb3VuZCUzQSUyMCUyM0UwRUNGRiUzQiUyMiUyMHJvd3NwYW4lM0QlMjIyJTIyJTNFJTNDc3Ryb25nJTNFTGVpc3R1bmclM0NiciUyMCUyRiUzRSU1QiUyMGluJTIwa1clMjAlNUQlM0MlMkZzdHJvbmclM0UlM0MlMkZ0aCUzRSUzQ3RoJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXRvcCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXJpZ2h0JTNBJTIwMHB4JTNCJTIwYmFja2dyb3VuZCUzQSUyMCUyM0UwRUNGRiUzQiUyMiUyMHJvd3NwYW4lM0QlMjIyJTIyJTNFJTNDc3Ryb25nJTNFRHJlaHphaGwlM0NiciUyMCUyRiUzRSU1QiUyMGluJTIwMSUyRm1pbiUyMCU1RCUzQyUyRnN0cm9uZyUzRSUzQyUyRnRoJTNFJTNDdGglMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAwcHglM0IlMjBib3JkZXItbGVmdCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXRvcCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXJpZ2h0JTNBJTIwMHB4JTNCJTIwYmFja2dyb3VuZCUzQSUyMCUyM0UwRUNGRiUzQiUyMiUyMGNvbHNwYW4lM0QlMjIyJTIyJTNFJTNDc3Ryb25nJTNFR2V3aWNodCUzQyUyRnN0cm9uZyUzRSUzQyUyRnRoJTNFJTNDdGglMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAycHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItdG9wJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItcmlnaHQlM0ElMjAwcHglM0IlMjBiYWNrZ3JvdW5kJTNBJTIwJTIzRTBFQ0ZGJTNCJTIyJTIwcm93c3BhbiUzRCUyMjIlMjIlM0UlM0NzdHJvbmclM0VCYW5kLSUzQ2JyJTIwJTJGJTNFc2NobGVpZmFybSUzQyUyRnN0cm9uZyUzRSUzQyUyRnRoJTNFJTNDdGglMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAycHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItdG9wJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItcmlnaHQlM0ElMjAwcHglM0IlMjBiYWNrZ3JvdW5kJTNBJTIwJTIzRTBFQ0ZGJTNCJTIyJTIwcm93c3BhbiUzRCUyMjIlMjIlM0UlM0NzdHJvbmclM0VQb2xpZXItJTNDYnIlMjAlMkYlM0VzcGl0emUlM0MlMkZzdHJvbmclM0UlM0MlMkZ0aCUzRSUzQ3RoJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXRvcCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXJpZ2h0JTNBJTIwMHB4JTNCJTIwYmFja2dyb3VuZCUzQSUyMCUyM0UwRUNGRiUzQiUyMiUyMHJvd3NwYW4lM0QlMjIyJTIyJTNFJTNDc3Ryb25nJTNFQWJzYXVnLSUzQ2JyJTIwJTJGJTNFaGF1YmVuLSVDMyU5OCUzQ2JyJTIwJTJGJTNFJTVCJTIwaW4lMjBtbSUyMCU1RCUzQyUyRnN0cm9uZyUzRSUzQyUyRnRoJTNFJTNDdGglMjBzdHlsZSUzRCUyMmJvcmRlciUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYmFja2dyb3VuZCUzQSUyMCUyM0UwRUNGRiUzQiUyMiUyMHJvd3NwYW4lM0QlMjIyJTIyJTNFJTNDc3Ryb25nJTNFQWItJTNDYnIlMjAlMkYlM0VzYXVndW5nJTNDJTJGc3Ryb25nJTNFJTNDJTJGdGglM0UlM0MlMkZ0ciUzRSUwQSUzQ3RyJTIwYWxpZ24lM0QlMjJjZW50ZXIlMjIlM0UlM0N0aCUyMHN0eWxlJTNEJTIyYm9yZGVyLWJvdHRvbSUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLWxlZnQlM0ElMjAlMjMwMDAlMjAycHglMjBzb2xpZCUzQiUyMGJvcmRlci10b3AlM0ElMjAwcHglM0IlMjBib3JkZXItcmlnaHQlM0ElMjAwcHglM0IlMjBiYWNrZ3JvdW5kJTNBJTIwJTIzRTBFQ0ZGJTNCJTIyJTNFJTNDc3Ryb25nJTNFNjAwJTIwbW0lM0NiciUyMCUyRiUzRSU1QiUyMGluJTIwa2clMjAlNUQlM0MlMkZzdHJvbmclM0UlM0MlMkZ0aCUzRSUzQ3RoJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMnB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMCUyMzAwMCUyMDJweCUyMHNvbGlkJTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMDBweCUzQiUyMGJhY2tncm91bmQlM0ElMjAlMjNFMEVDRkYlM0IlMjIlM0UlM0NzdHJvbmclM0UxLjAwMCUyMG1tJTNDYnIlMjAlMkYlM0UlNUIlMjBpbiUyMGtnJTIwJTVEJTNDJTJGc3Ryb25nJTNFJTNDJTJGdGglM0UlM0MlMkZ0ciUzRSUwQSUzQ3RyJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwJTIzMDAwJTIwMXB4JTIwc29saWQlM0IlMjBib3JkZXItdG9wJTNBJTIwMHB4JTNCJTIwYm9yZGVyLXJpZ2h0JTNBJTIwJTIzMDAwJTIwMXB4JTIwc29saWQlM0IlMjIlMjByb3dzcGFuJTNEJTIyNSUyMiUyMGFsaWduJTNEJTIyY2VudGVyJTIyJTNFU01aJTIwNTclM0MlMkZ0ZCUzRSUwQSUzQ3RkJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMXB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMDBweCUzQiUyMGJvcmRlci10b3AlM0ElMjAwcHglM0IlMjBib3JkZXItcmlnaHQlM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMiUyMGFsaWduJTNEJTIyY2VudGVyJTIyJTNFNCUyQzAlM0MlMkZ0ZCUzRSUwQSUzQ3RkJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMXB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMDBweCUzQiUyMGJvcmRlci10b3AlM0ElMjAwcHglM0IlMjBib3JkZXItcmlnaHQlM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMHBhZGRpbmctbGVmdCUzQSUyMDVweCUzQiUyMiUyMHJvd3NwYW4lM0QlMjIzJTIyJTNFMiUyMHglMjAzLXN0dWZpZyUzQ2JyJTIwJTJGJTNFMS4yMDAlMjBiaXMlMjAzLjUwMCUzQyUyRnRkJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwMHB4JTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIyJTIwcm93c3BhbiUzRCUyMjMlMjIlMjBhbGlnbiUzRCUyMmNlbnRlciUyMiUzRTIzMCUzQyUyRnRkJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwMHB4JTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIyJTIwcm93c3BhbiUzRCUyMjMlMjIlMjBhbGlnbiUzRCUyMmNlbnRlciUyMiUzRTI3NSUzQyUyRnRkJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwMHB4JTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIwcGFkZGluZy1sZWZ0JTNBJTIwNXB4JTNCJTIyJTIwcm93c3BhbiUzRCUyMjMlMjIlM0VNb2RlbGwlMjBFQiUyMDMtUyUzQ2JyJTIwJTJGJTNFQmFuZGFibWVzc3VuZ2VuJTNBJTNDYnIlMjAlMkYlM0UxMDAlMjB4JTIwMy41MDAlMjBtbSUzQyUyRnRkJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwMHB4JTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIyJTIwcm93c3BhbiUzRCUyMjMlMjIlMjBhbGlnbiUzRCUyMmNlbnRlciUyMiUzRU0lMjAxNiUzQyUyRnRkJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwMHB4JTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIyJTIwcm93c3BhbiUzRCUyMjMlMjIlMjBhbGlnbiUzRCUyMmNlbnRlciUyMiUzRTQwMCUzQ2JyJTIwJTJGJTNFNTAwJTNDJTJGdGQlM0UlMEElM0N0ZCUyMHN0eWxlJTNEJTIyYm9yZGVyLWJvdHRvbSUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIwYm9yZGVyLWxlZnQlM0ElMjAwcHglM0IlMjBib3JkZXItdG9wJTNBJTIwMHB4JTNCJTIwYm9yZGVyLXJpZ2h0JTNBJTIwJTIzMDAwJTIwMXB4JTIwc29saWQlM0IlMjIlMjByb3dzcGFuJTNEJTIyMyUyMiUyMGFsaWduJTNEJTIyY2VudGVyJTIyJTNFQXVmJTNDYnIlMjAlMkYlM0VBbmZyYWdlJTNDJTJGdGQlM0UlMEElM0MlMkZ0ciUzRSUwQSUzQ3RyJTNFJTBBJTNDdGQlMjBzdHlsZSUzRCUyMmJvcmRlci1ib3R0b20lM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMGJvcmRlci1sZWZ0JTNBJTIwMHB4JTNCJTIwYm9yZGVyLXRvcCUzQSUyMDBweCUzQiUyMGJvcmRlci1yaWdodCUzQSUyMCUyMzAwMCUyMDFweCUyMHNvbGlkJTNCJTIyJTIwYWxpZ24lM0QlMjJjZW50ZXIlMjIlM0U1JTJDNSUzQyUyRnRkJTNFJTBBJTNDJTJGdHIlM0UlMEElM0N0ciUzRSUwQSUzQ3RkJTIwc3R5bGUlM0QlMjJib3JkZXItYm90dG9tJTNBJTIwJTIzMDAwJTIwMXB4JTIwc29saWQlM0IlMjBib3JkZXItbGVmdCUzQSUyMDBweCUzQiUyMGJvcmRlci10b3AlM0ElMjAwcHglM0IlMjBib3JkZXItcmlnaHQlM0ElMjAlMjMwMDAlMjAxcHglMjBzb2xpZCUzQiUyMiUyMGFsaWduJTNEJTIyY2VudGVyJTIyJTNFNyUyQzUlM0MlMkZ0ZCUzRSUwQSUzQyUyRnRyJTNFJTBBJTNDJTJGdGJvZHklM0UlMEElM0MlMkZ0YWJsZSUzRQ==waves-Ø: 35 mm

max. Kontaktscheiben-Ø: 450 mm

max. polishing wheel Ø: 500 mm

Voltage: 400 V, 50 Hz

Operating mode: S1, IP 54(click table to enlarge)