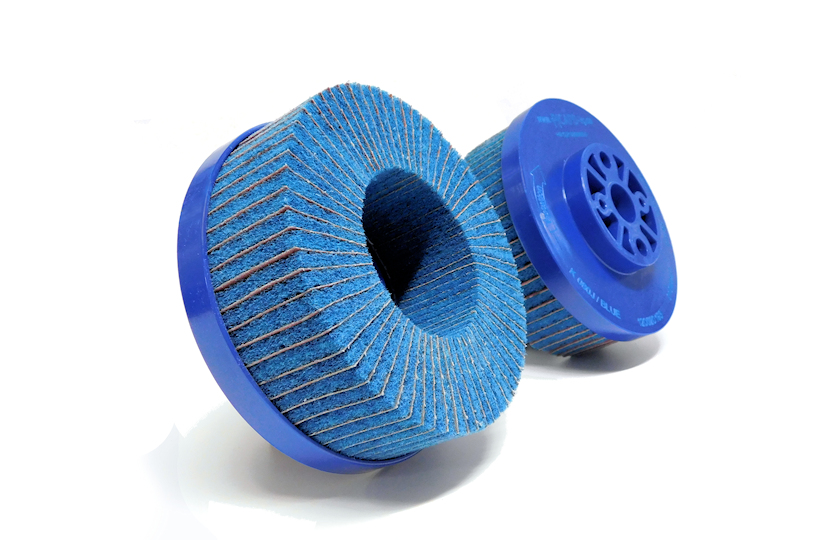

The deburring grinding discs of the FAPI-150 series are the ideal tool for deburring on automatic and manual deburring machines (e.g. our deburring machine FAPI-STARGRINDER) and are particularly suitable for processing larger series.

Product features

- Shortest set-up times

The 25 mm bore and 4 driver holes enable easy assembly and positioning of the FAPI-150 deburring grinding disk on the deburring machine.

- A wide variety of trim materials

By selecting different densities, trim lengths, types of abrasive cloth and abrasive fleece, you can have a decisive influence on the deburring process. The optimal design of the deburring grinding disc FAPI-150 can be determined from the process parameters dry or wet grinding, the material to be processed, the material thickness and the desired surface quality or the desired roughness depth.

- Picard tip

The coarser the grain size of the FAPI-150 deburring sander is selected, the greater the edge rounding on the workpiece.

- Individual slat positions

The deburring sanding disc FAPI-150 has abrasive cloth slats attached to the front, which are supported by abrasive fleece slats. Due to the special position of the lamellae, FAPI-150 deburring grinding discs can be manufactured individually for the respective machining process.

- Made in Germany

Without exception, all Picard tools and naturally also our deburring discs series are made in Germany. High quality and optically outstanding grinding tools are the results of our production and you, as our customer, benefit from this.

Facing types

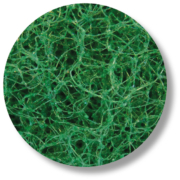

PICARD GREEN

(standard-fleece) | The soft one!

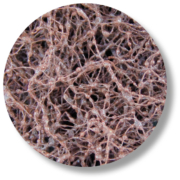

PICARD BROWN

(standard-fleece) | The all-rounder!

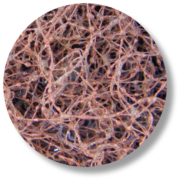

PICARD MAROON

(standard-fleece) | Sets standards in removal!

PICARD SAND

(special fleece) | The one with the bite!

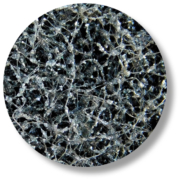

PICARD DARKGREY

(premium fleece) | The supple one!

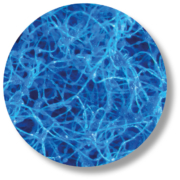

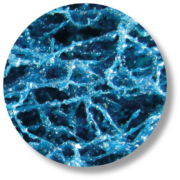

PICARD BLLUE

(premium fleece) | The self-sharpener!

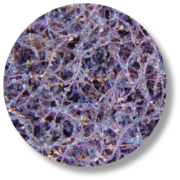

PICARD VIOLET

(premium fleece) | Noble thing!

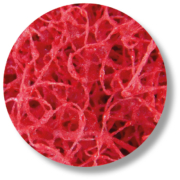

PICARD RED

(special fleece) | Coarse and strong!

PICARD DARKBLUE

(special fleece) | Wide, durable and flexible!

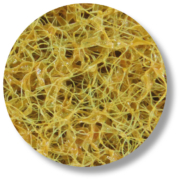

PICARD YELLOW

(special fleece) | Wet & Dry!-The versatile one!

PICARD GRV

(special fleece) | The water-resistant one!

For more information about the abrasive fleece qualities, please click here.

The deburring result can be decisively influenced by the selected abrasive fleece quality and the fill arrangement (single-row, double-row or triple-row).

We will be happy to advise you!