The further development of our deburring grinding plates are our patented deburring segments FAPI-FLEX-SAT (patent no. DE20304860 U1).

These advanced deburring segments were developed in collaboration with the company Timesavers from the Netherlands. Fast, safe and clean deburring or edge rounding of sheet metal parts is no longer a problem when using these tools. Deburring grinding segments can also be individually adapted depending on the application.

We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

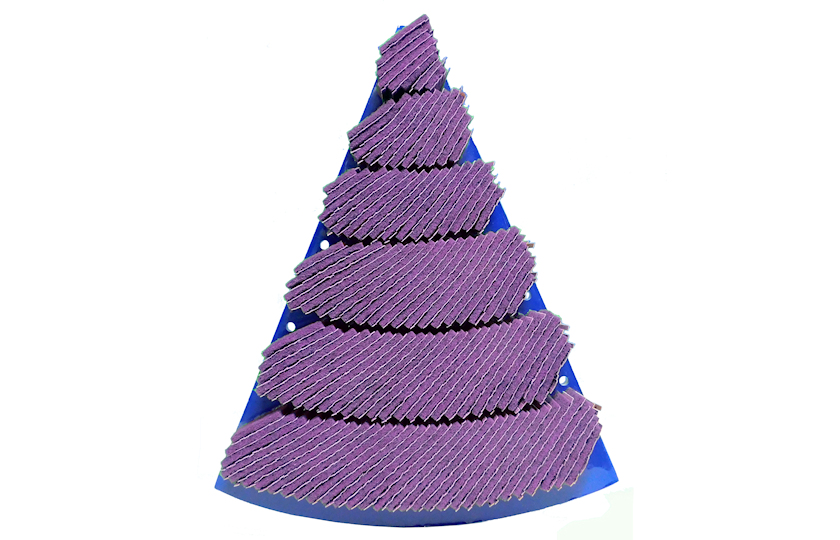

For further information about the abrasive fleece qualities please click here.In the deburring grinding segments, abrasive cloth and abrasive fleece are alternately applied to a triangular carrier part. Both abrasive cloth and abrasive fleece can be selected in terms of grain size and quality upon customer request. In addition, the so-called division between abrasive cloth and abrasive fleece can be varied as desired.

Eight deburring segments result in a closed circle. This can then be used for deburring on a Timesavers machine.The deburring grinding segments and Timesavers machines are primarily used in the sheet metal processing industry.

Metal processing:

For example, after the sheet metal has been punched, flame cut, lasered or cut with a water jet, a burr usually forms at the interface. This can be removed using a Timesavers machine including the associated deburring segments.Diameter: 900 mm / 1200 mm / 1500 mm

Grain: 80 / 100 / 120 / 150