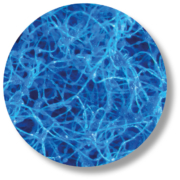

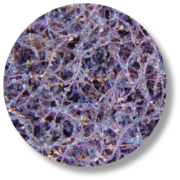

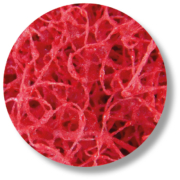

For more information about the abrasive fleece qualities, please click here.

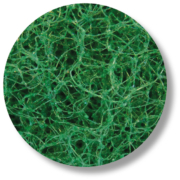

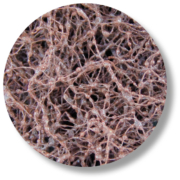

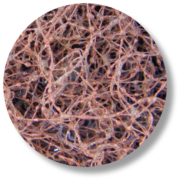

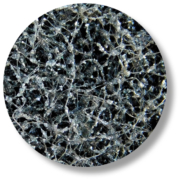

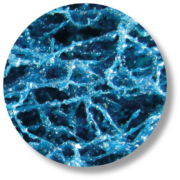

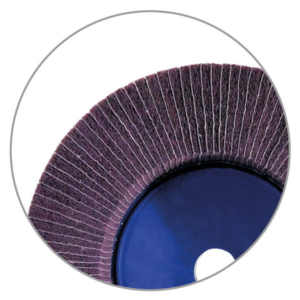

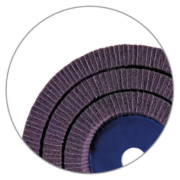

The deburring result can be decisively influenced by the selected abrasive fleece quality and the fill arrangement (single-row, double-row or triple-row).

We will be happy to advise you!

single row

single row  double-row

double-row three-row

three-row